7 min read

Every Minute Matters: How Veryon AIRE Is Shaping the Rules of Predictive Maintenance in Commercial Aviation

Veryon : Updated on December 2, 2025

Contents

Discover how Veryon AIRE transforms commercial aviation maintenance with intelligence that improves dispatch reliability, accelerates troubleshooting, and strengthens fleet performance.

In commercial aviation, time isn't just money. It's everything. It's the heartbeat of an entire operation that has to move in perfect rhythm. One delay can spiral into missed departure slots, aircraft swaps, and frustrated passengers.

And yet, airlines are sitting on mountains of maintenance data every single day. The problem? Most of it lives in silos, disconnected from the decisions that could have stopped the disruption before it ever reached the gate.

That's where Veryon AIRE comes in. Think of it as aviation's brain for proactive maintenance and reliability. Built on two decades of applied AI expertise, Veryon AIRE blends predictive analytics, natural language processing, and machine learning to help airlines spot issues earlier, fix them faster, and keep schedules running exactly as planned.

The Real Cost of "Wait and See"

Anyone who's worked in airline maintenance knows the sinking feeling when an unexpected snag turns into a full-blown delay. One aircraft on the ground can throw the entire operation off balance, forcing aircraft swaps, backup calls, and a chain of cancellations that ripple across the network.

According to IATA, every minute of delay costs airlines around $74. And that doesn't even include the downstream effect of missed crew connections, rebooked passengers, and mounting schedule chaos.

The frustrating part is that most of these disruptions aren't surprising. The warning signs are there, hidden in logbooks, fault codes, and write-ups, but scattered and impossible to act on in real time.

Veryon AIRE connects the dots automatically, turning all that raw maintenance data into something every airline needs more of: foresight.

Veryon AIRE: Intelligence for When Every Minute Matters

Veryon AIRE brings together the largest collection of de-identified aviation maintenance data anywhere - more than 80 million maintenance events and 1.3 million parts – and combines it with each operator's live fleet data. The result is a system that can spot patterns, predict risks, and point maintenance teams toward the fixes that actually work for their specific aircraft and configurations.

It's not just data for data's sake. It's real, usable intelligence that helps operators stay ahead of problems instead of chasing them.

Here's what that looks like in action:

Smarter, faster fixes

Discover the most probable fixes for issues, increasing first-time-fix rates. Enable technicians to ask publication-specific questions and jump straight into maintenance tasks.

Intelligent fleet management

Automate routine work, reduce costs, and optimize your most critical maintenance and inventory tasks.

Enhanced reliability

Surface chronic patterns, rogue/short-life components, and trend degradation early, before they escalate and cause unexpected AOGs.

For SVPs of Maintenance and Engineering, that means safeguarding on-time performance and operational margins. For Maintenance Control, it's about stopping repeat write-ups and making quicker go or no-go decisions. And for Reliability teams, it's having an early warning system that spots component risks and failure trends long before they disrupt operations.

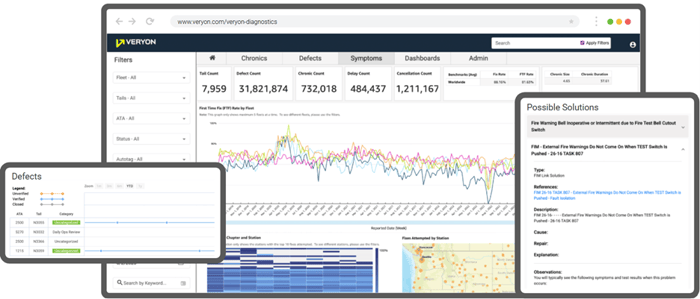

Veryon Diagnostics: From Data to Decision in Real Time

Veryon Diagnostics, powered by Veryon AIRE, digs into millions of maintenance events every month to spot chronic issues, catch repeating defects, and surface real-world fixes that have already worked across similar fleets.

Using advanced Natural Language Processing, or NLP, Veryon Diagnostics can actually read the unstructured notes that technicians enter into maintenance logs. Think of phrases like "oil leak observed at gate 47" or "autopilot disengaged during climb." The system understands that language, connects it to known defect patterns, and highlights the most likely causes along with the corrective actions that have solved the issue before.

It turns reactive troubleshooting into guided problem-solving. Maintenance Control teams and line technicians get immediate, data-backed insight into what to do next so they can move faster and with more confidence.

The results speak for themselves. Operators using Veryon Diagnostics have seen troubleshooting times drop by up to 75 percent and downtime costs reduced by about 23 percent. Those gains translate directly to stronger reliability and better on-time performance.

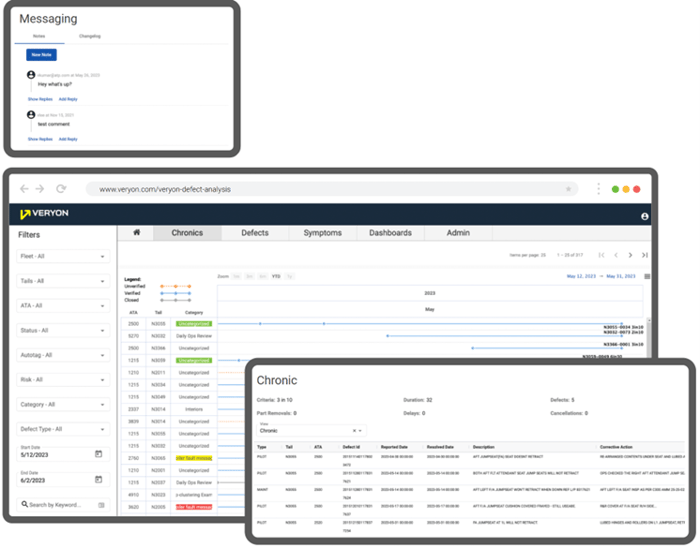

Veryon Defect Analysis: Seeing Patterns Before They Disrupt

Even the most advanced airlines deal with repeat issues. Those chronic defects that get fixed one week, only to show up again the next. Veryon Defect Analysis, fueled by Veryon AIRE, is built to stop that cycle by automatically spotting recurring trends across an airline's fleet before they turn into something bigger.

Veryon AIRE works behind the scenes in Veryon Defect Analysis to identify and cluster recurring defects that could otherwise go unnoticed, so you can find a fix before it grounds an aircraft.

The system groups similar maintenance events using NLP and machine learning, then flags defects that keep triggering corrective actions without lasting results. Once it finds the pattern, it layers in context like environmental conditions, flight phase, and component history to uncover the real root cause.

For Reliability and Maintenance Control teams, that means catching chronic issues earlier, long before they start disrupting schedules. The system even ranks corrective actions by how effective they've been in the past, giving teams the data they need to finally put repeat problems to rest.

Repeat defects are one of the biggest drivers of AOGs and dispatch delays. By bringing these patterns to light, Veryon Defect Analysis helps operators move from constantly reacting to actually staying ahead. And that shift changes everything about how maintenance gets done.

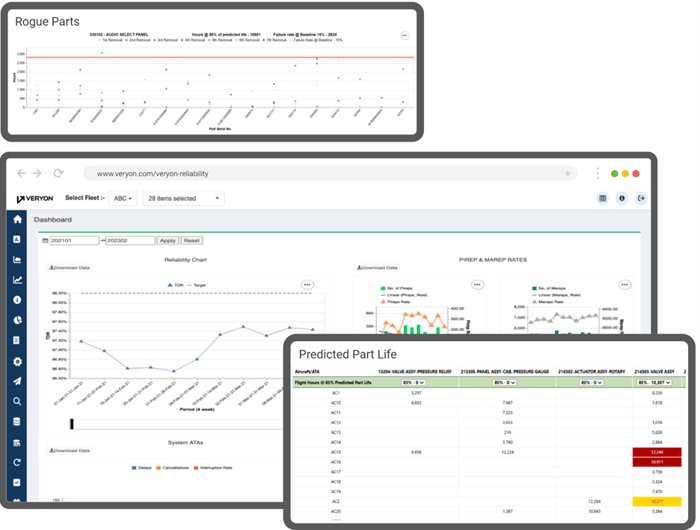

Veryon Reliability: Foresight for the Entire Fleet

While Veryon Diagnostics and Veryon Defect Analysis handle what's happening right now, Veryon Reliability looks further ahead. It gives airlines the ability to see what's coming weeks or even months in advance.

Using predictive models built from Veryon AIRE's massive global dataset, Veryon Reliability can forecast component failures, spot emerging reliability risks, and help teams plan spares more intelligently. The goal is simple: move from reacting to problems to staying ahead of them.

Instead of waiting for something to break, engineering and planning teams can schedule maintenance around predicted removal windows and degradation trends. That shift not only reduces downtime but also helps airlines avoid surprise AOGs altogether.

Veryon Reliability also automates FAA-required reporting, such as CASS, so operators can stay compliant while gaining deeper insight into their fleet's performance.

The real win, though, is strategic. Veryon AIRE's predictive analytics give maintenance leaders the data to defend budgets, optimize parts inventory, and prove ROI with hard reliability metrics. Behind the scenes, Veryon AIRE continuously ingests, analyzes, and cleans aircraft reliability data within the Veryon Reliability platform, transforming it into predictive insights that drive better decisions and stronger fleet performance.

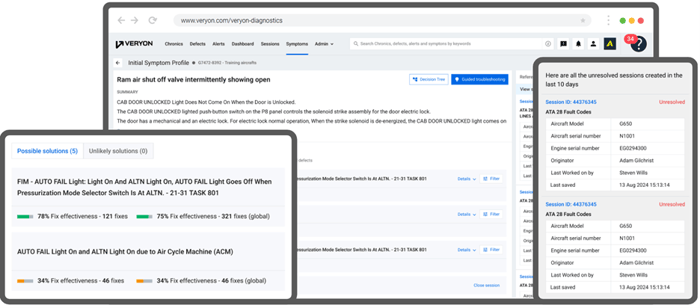

Veryon Guided Troubleshooting: From Guesswork to Precision

Line maintenance is high stakes. Every minute an aircraft sits on the ground is a hit to schedules, revenue, and crew coordination. Technicians need to find the fault quickly, often with limited information and mounting pressure. Veryon Guided Troubleshooting, powered by Veryon AIRE, completely changes that experience.

It functions as a step-by-step diagnostic assistant, combining structured technical data with the collective knowledge of the field. By analyzing de-identified fleet-wide data, it ranks potential causes and corrective actions by their likelihood of solving the problem.

Veryon AIRE in Veryon Guided Troubleshooting provides predictive fix recommendations based on proven, real-world maintenance outcomes from thousands of similar aircraft events. So instead of starting from scratch, technicians can immediately see what's worked before — and why.

Suppose a mechanic is facing an engine oil leak, for example. In that case, Veryon AIRE instantly surfaces similar cases from across the global fleet, showing which fixes were most effective for that specific aircraft type and operating conditions. It also links directly to the relevant sections of the Troubleshooting Manual and Aircraft Maintenance Manual, helping techs move from symptom to verified fix without wasting time.

Early adopters of Veryon Guided Troubleshooting have seen noticeable improvements in first-time-fix rates and far less time wasted on broad, trial-and-error fault isolation. By embedding predictive intelligence right into the workflow, Veryon has turned troubleshooting from a stressful guessing game into a faster, more confident process that keeps aircraft flying.

Built for Aviation. Proven by Results.

The real power of Veryon AIRE isn't just in the tech itself. It's in how that tech is shaped, tested, and trusted by the people who actually live and breathe aviation.

Every AI model behind Veryon AIRE is trained and refined by aviation professionals who understand what every data point really means in the context of day-to-day operations. The system keeps learning from anonymized fleet data across global operators, so every recommendation feels less like guesswork and more like guidance from someone who's been there before.

Before anything goes live, Veryon's aviation experts and trusted airline partners test each capability in real-world conditions. That's why the AI never feels like a black box. Every recommendation is backed by traceable reasoning and links straight to the original maintenance data, giving teams full visibility and confidence in every decision.

Security and control are just as critical. All Veryon AIRE models are managed in-house, with full encryption and role-based access controls. Every system-generated recommendation is tracked and verified, and no data ever leaves the secure Veryon environment. That makes it safe for airlines to integrate Veryon AIRE into key systems such as M&E platforms, ERP suites, and reliability databases without increasing risk.

And the results? They're hard to ignore. Early adopters of Veryon AIRE are already seeing:

- 23% lower downtime costs thanks to faster detection and targeted fixes

- 75% faster troubleshooting by surfacing proven solutions automatically

- Better dispatch reliability with fewer maintenance-related cancellations

When you apply those results across hundreds of aircraft and thousands of flights, the impact grows fast. Airlines are protecting their schedules, freeing up maintenance capacity, and using data to make smarter decisions about parts and planning. It's the kind of operational lift that doesn't just look good on paper — it changes how maintenance gets done in the real world.

Veryon AIRE as an Intelligence Platform

The real power of Veryon AIRE lies in how it connects all of Veryon's solutions into one continuous system of intelligence. Within the Diagnostics suite, the modules Defect Analysis, Reliability, and Guided Troubleshooting work together, each feeding the next.

- Veryon Defect Analysis spots the issue and determines if it's recurring.

- Veryon Reliability predicts when the next event will happen.

- Veryon Guided Troubleshooting ensures it's fixed right the first time.

Each solution strengthens the next, creating a constant flow of data and insight where information doesn't just describe what happened but actively prevents it from happening again.

That's what makes Veryon AIRE more than just artificial intelligence. It's a living, learning network designed to keep aircraft where they belong, in the air.

Looking Ahead

Predictive maintenance is no longer a futuristic goal for commercial aviation. It's happening right now, powered by tools like Veryon AIRE that blend human experience with machine intelligence.

For an industry defined by precision, timing, and safety, this shift represents more than operational improvement. It's a transformation in how airlines think about reliability—from reactive to proactive, from hindsight to foresight.

And as fleets grow more complex and data volumes expand exponentially, one truth will remain: in aviation, every minute still matters.

Get started with Veryon AIRE

See Veryon AIRE in action and explore how it can streamline your operation. Fill out the form, and we'll schedule a custom demo tailored to your workflow.

Want more resources?

Explore Veryon's full library of expert content and aviation insights — from maintenance tracking to diagnostics, predictive reliability, and beyond.

Stay connected

Join thousands of aviation professionals who turn to Veryon for insights on predictive maintenance, industry innovation, and emerging tech trends.

Follow Veryon on LinkedIn and be part of the conversation driving aviation's digital transformation.