AI-Powered Defect Analysis

Automatically identify, cluster, and analyze repeat aircraft defects with the help of Veryon AIRE—our AI technology, so you can find the right fix faster.

Get started with a demo of Veryon Diagnostics

Just fill out the form and we'll be in touch.

Make sense out of all that data

Find issues before they escalate

Natural language processing (NLP) identifies repetitive defects after just two occurrences, enabling faster resolutions that keep aircraft in service and reduce operational disruptions.

Unlock the full potential of integrated insights

Combine sensor data with defect analysis to uncover hidden patterns, ensuring a deeper understanding of performance issues and empowering proactive maintenance.

Eliminate costly delays and downtime

Streamline your maintenance processes

Benefit from automated logbook updates, advanced hyperlink integrations, and mobile access to ensure complete coordination across teams and locations.

Improve maintenance accuracy

Get better first-time-fix rates with collaborative troubleshooting, reasoning engines, and symptom profile views that save time and resources.

Calculate your ROI

Enter your fleet count to estimate your potential return on investment from adopting Defect Analysis. We've made assumptions for key metrics based on industry averages, but feel free to override these with your own figures.

Return on investment

ROI of to 1

This is the estimated additional revenue you could earn per year for every dollar spent on our solution.

Defect Analysis empowers you to reduce delays and cancellations, allowing aircraft to generate maximum revenue. It can also cut your spend on unnecessary parts by identifying the correct fix faster.

Fill out the form below and we'll set up a call to go through your full results.

FEATURES AND FUNCTIONALITY

Minimize unscheduled maintenance

Utilize natural language processing and data analysis to identify, analyze, and act on unscheduled maintenance events before they occur. With our technology you can see reductions of up to:

In repeating defects

In unscheduled removals

In cancellations and delays

Select an option below:

- Key Features

- Mobile App

- Feature Checklist

![]()

AI defect clustering

Accurately identify repeat defects from across your fleet with Veryon AIRE, so you can find and resolve issues sooner.

Enhanced fix effectiveness

Leverage first-time fix programs, collaborative troubleshooting, and reasoning engines to optimize maintenance outcomes.

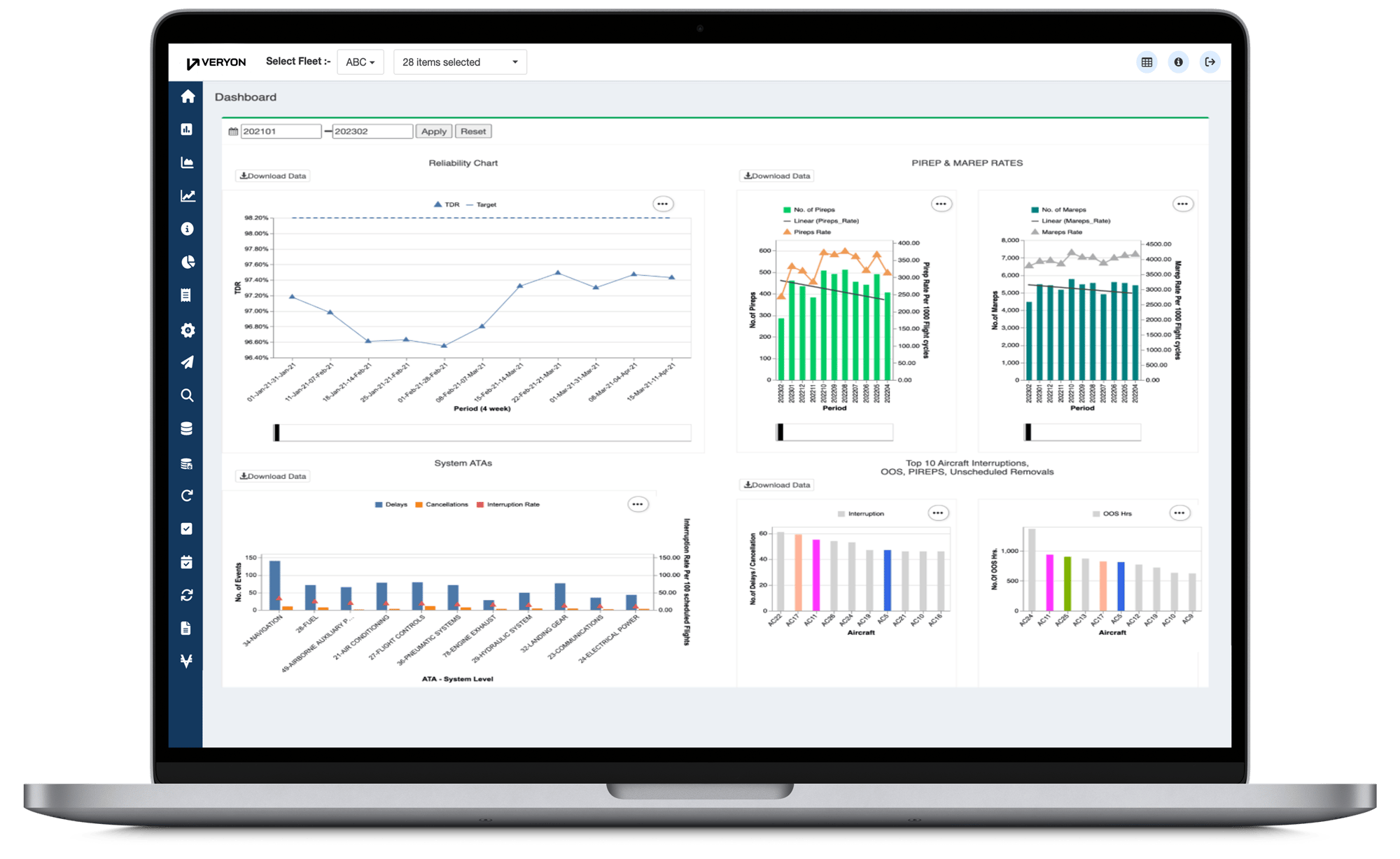

Customizable dashboards

Tailor dashboards and reports to track defects and trends effectively.

Advanced data integration

Combine sensor data with defect analysis for comprehensive performance insights.

Hyperlinked M&E integrations

Quickly access critical data directly through hyperlinks to your M&E systems.

Part and serial monitoring

Track part reliability to identify correlations with delays and improve operational efficiency.

Intelligent identifcation and analysis

Defect Analysis overcomes the hurdles of defect classification and clustering, and allows for quick issue resolution.

Get started with a demo of Veryon Diagnostics

Just fill out the form and we'll be in touch.

| Defect Clustering | |

| Advanced Filters | |

| Advanced Search | |

| Custom Categories | |

| Chronic Details | |

| Comment and Share | |

| Risk Assignment |

| Split Chronics | |

| Move Defects | |

| Recycle Defects | |

| Defect Histories | |

| ATA Histories | |

| Tail Histories | |

| Initial Symptom Profiles |

| Fix Categorization | |

| Custom Alerts | |

| Customizable Dashboards | |

| Benchmark Reports | |

| Fix Effectiveness Monitoring | |

| Parts Tracking |

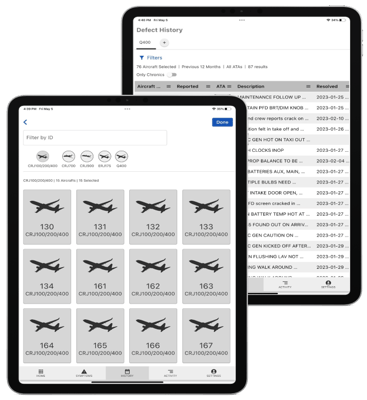

Track defects in the field

Equip your line technicians with our user-friendly mobile application for real-time defect management on the ramp or in the hangar. Get detailed tail histories and defect timelines at your fingertips for on-the-job troubleshooting.

"Prior to getting Veryon Defect Analysis, we would have to do a broad search of all write-ups, extract them into Excel, filter them, and try to find all the items tied to them, and there could be hundreds of thousands of write-ups. When we implemented Veryon Defect Analysis, it immediately told us, 'Well, here’s your write-ups that are all tied together.' It made it much simpler to see the history of what’s happening with it."

Manager of Maintenance Control Regional Airline

OTHER SOLUTIONS

Defect Analysis works better with...

Reliability

Boost fleet performance by identifying short-life parts, rogue components, and seasonal trends.

Guided Troubleshooting

Improve your first-time fix rates with expert guidance for your technicians.

Get started with a demo

See for yourself how Veryon Diagnostics can get your aircraft more uptime. Fill out the form and our team will set up a tailor-made demonstration.

Not ready for a demo?

Reach out to the team with any questions, or get a quote to understand our pricing.

How can we help?

Just fill out the form and we'll get in touch.

Get a quote

Share a few details about your project so we can provide an estimate.