5 min read

Aviation Management Software Trends: What's New in Aircraft Uptime Optimization and What’s to Come

Veryon : Updated on April 18, 2025

Aviation software is completely revolutionizing the industry and propelling it toward a safer, more efficient, and more sustainable future. With a more intuitive technology platform that can manage everything from maintenance to manuals, anything is possible.

In most industries, modern software is something that is often discussed, but not always employed. But in the fast-paced world of aviation, it’s necessary. Your team needs accurate, timely information, and the ability to access data immediately to keep your operation running smoothly -- especially when things are changing by the second.

In this blog, we’ll discuss the top aviation trends in the industry, hear from experts in the field, and highlight what’s new in software and solutions.

Top 5 Aviation Software Trends

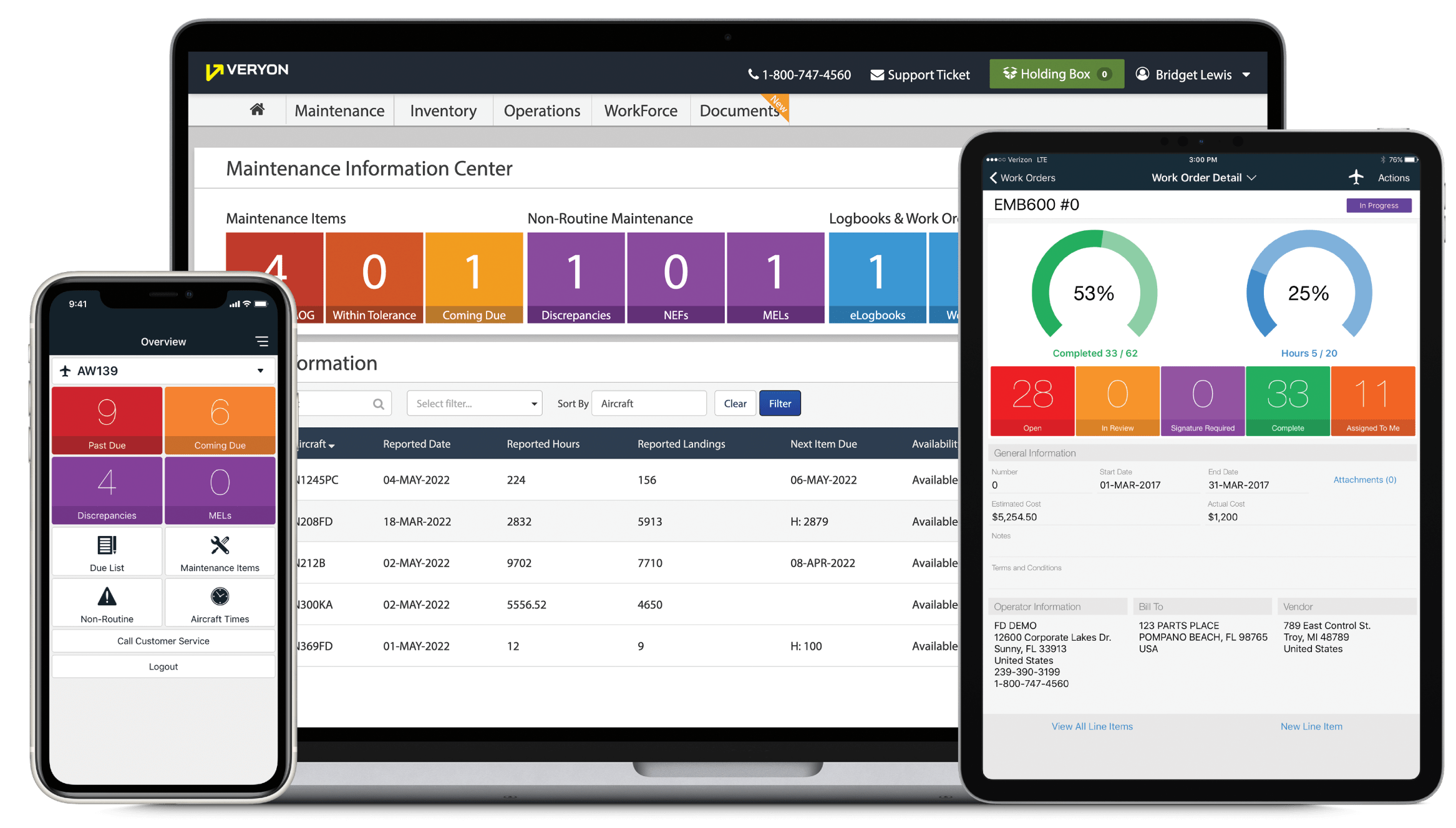

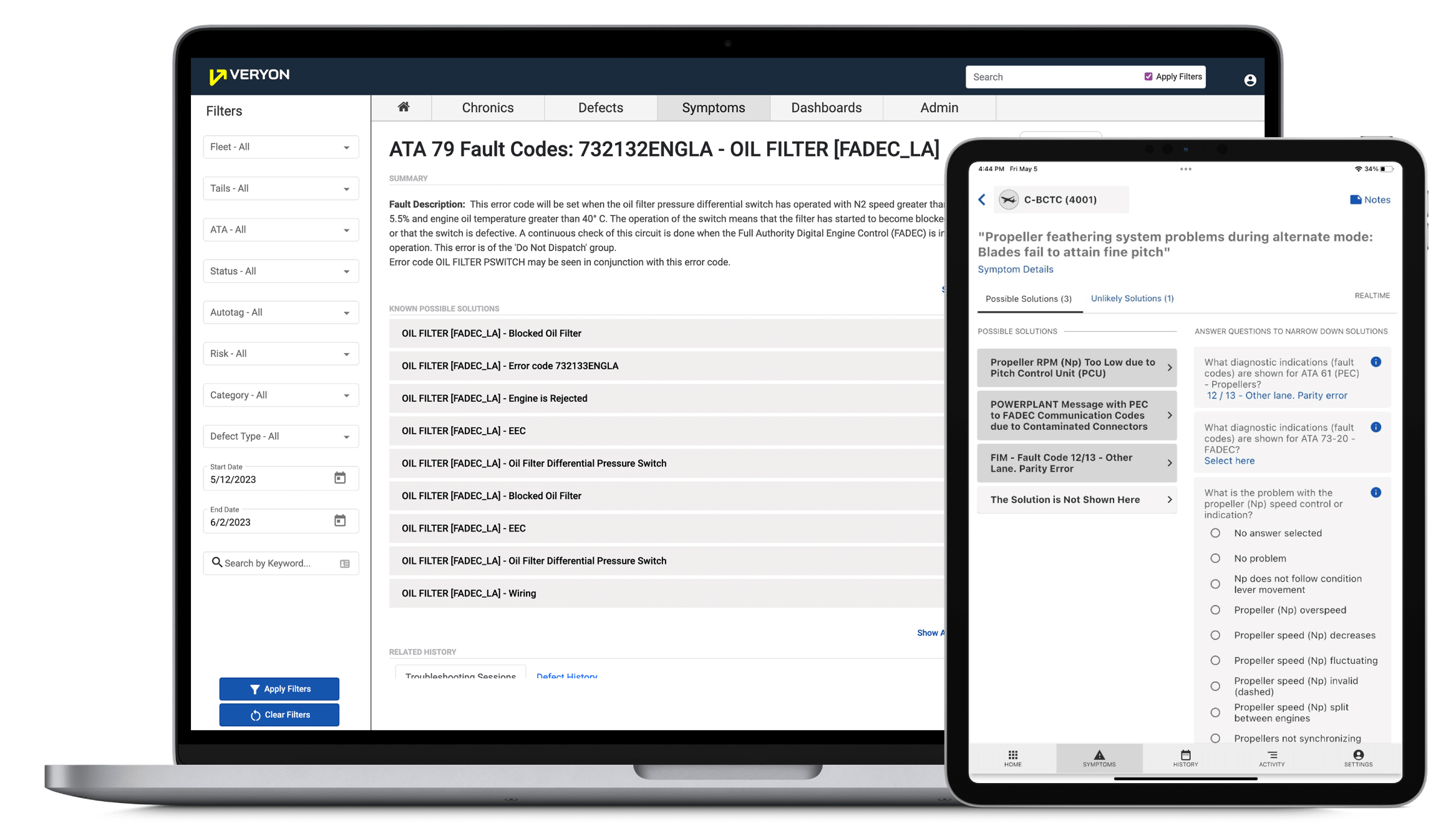

1. Mobile Apps: Remember having to print out pages upon pages of directions from MapQuest to get you to an unfamiliar destination? Today’s technology is more accessible than ever before, and most times, right in the palm of your hand. A great software program should have a mobile application that offers secure and reliable data and keeps you updated from any corner of the globe, using a smartphone or tablet.

“Pilots have had iPads in the cockpit for a while now, but seeing technicians use them in the hangar or on the road is increasingly more common,” said John Koci, Customer Success Manager for Veryon. “Just having access to the aircraft data from your phone can be a lifesaver when you’re not at the hangar, and drastically reduce downtime when you need to quickly order a part or update the aircraft status. There are many other ways to highlight the need for mobile capabilities, but ultimately this allows a technician or Director of Maintenance (DOM) to manage the paperwork part of their job from anywhere and not be tied to their desk.”

2. Real-Time Visibility: Accessing data quickly is sometimes mission-critical. A top trend in maintenance tracking software is something that gives you real-time visibility that includes total times, items due, discrepancies, logbooks, and work orders — all from one simplified dashboard.

“We’re seeing an increase in moving towards real-time troubleshooting, including e-logbooks and mobile maintenance tracking platforms embedded with predictive analytics,” said Fedor Gorin, Senior Director of Engineering for Veryon.

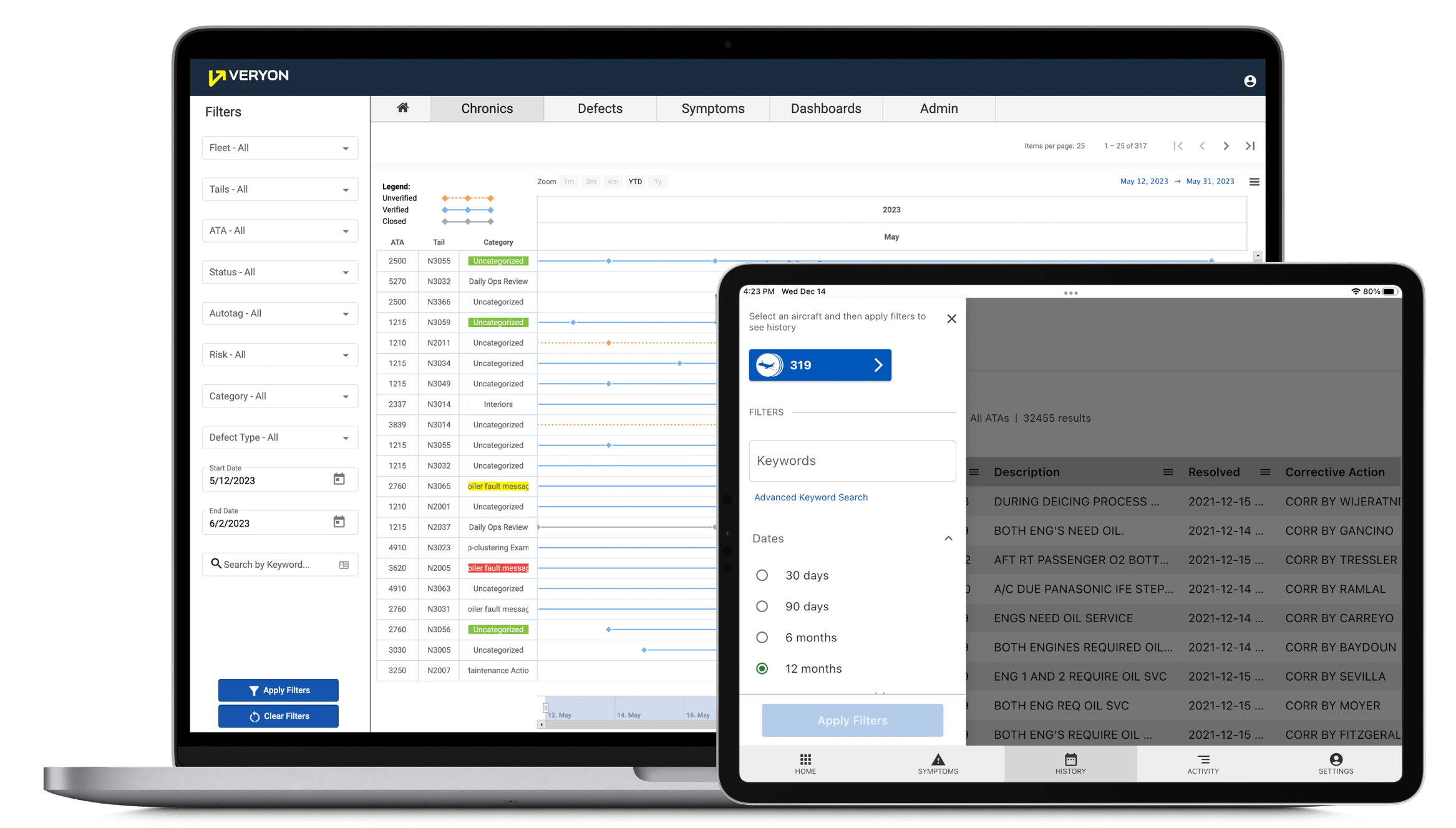

3. Artificial Intelligence and Machine Learning: The strategic utilization of artificial intelligence and machine learning in aviation software is beginning to have a positive effect, leading to optimized operational efficiency. When combined with the expertise of knowledgeable data analysts and technicians, we are moving closer to more predictive and valuable analysis of historical information and trends.

Veryon Defect Analysis is currently in use on 25% of the world’s commercial airline fleet to help achieve a 10% reduction in cancellations and delays. It also detects emerging failure modes that are yet to reach critical status. Custom-targeted alerts enable engineers to respond with greater speed and accuracy.

33% Reduction

in chronic and repeating defects.

20% Reduction

in unscheduled part removal rates.

10% Reduction

in cancellations and delays.

4. Integration Across Platforms: Did you know that breaking down silos with a single solution can increase your operational efficiencies by 20%? An all-in-one solution helps to streamline processes, improve visibility, reduce costs, predict maintenance, improve collaboration, and reduce errors.

“We continue to see a desire to consolidate or integrate software tools,” said Stephanie Hart, Chief Customer Officer for Veryon. “As well as getting more information at the fingertips of frontline mechanics to support them in keeping aircraft flying.”

5. Platforms That Are Constantly Changing: Particularly when it comes to an all-cloud platform, scalability, and availability are important things to keep in mind. Every time the usage of the platform changes, the platform should adapt to that. With the ultimate goal being for operators to get their aircraft more uptime, utilizing a technology platform that is constantly evolving is key to achieving that.

“2023 has seen an accelerated move off of legacy Windows-based and clunkier web-based software,” said Kent Pickard, Vice President of Product for Veryon. “People are looking for solutions that help with the continued challenges of long lead times in sourcing parts and an ever more distributed workforce. While much of the work in aviation still happens at an airport or in the hangar and can’t be fully remote, many companies are standing up small-scale aircraft on ground (AOG) operations or opening new bases. Modern cloud-based software helps make that much more straightforward.”

Wes Hyduke, Veryon Senior Product Manager, succinctly captures the evolving landscape of post-pandemic Business Aviation.

“From a market perspective, post-pandemic Business Aviation activity continues to soar. Year-to-date, 2023 has had 27% more flights (Jets & Turboprop Part 91 / Part 135) compared to the same period in pre-pandemic 2019. The increased flight hours have created more demand for maintenance services while the increased flight schedules have challenged maintenance facilities to diligently plan their maintenance schedules, including efficient airline inventory management, to maximize their aircraft uptime. As a result, operators are increasingly adopting digital technologies to improve the efficiencies and accuracies of managing and monitoring their maintenance activities.”

What's new in aviation software at Veryon?

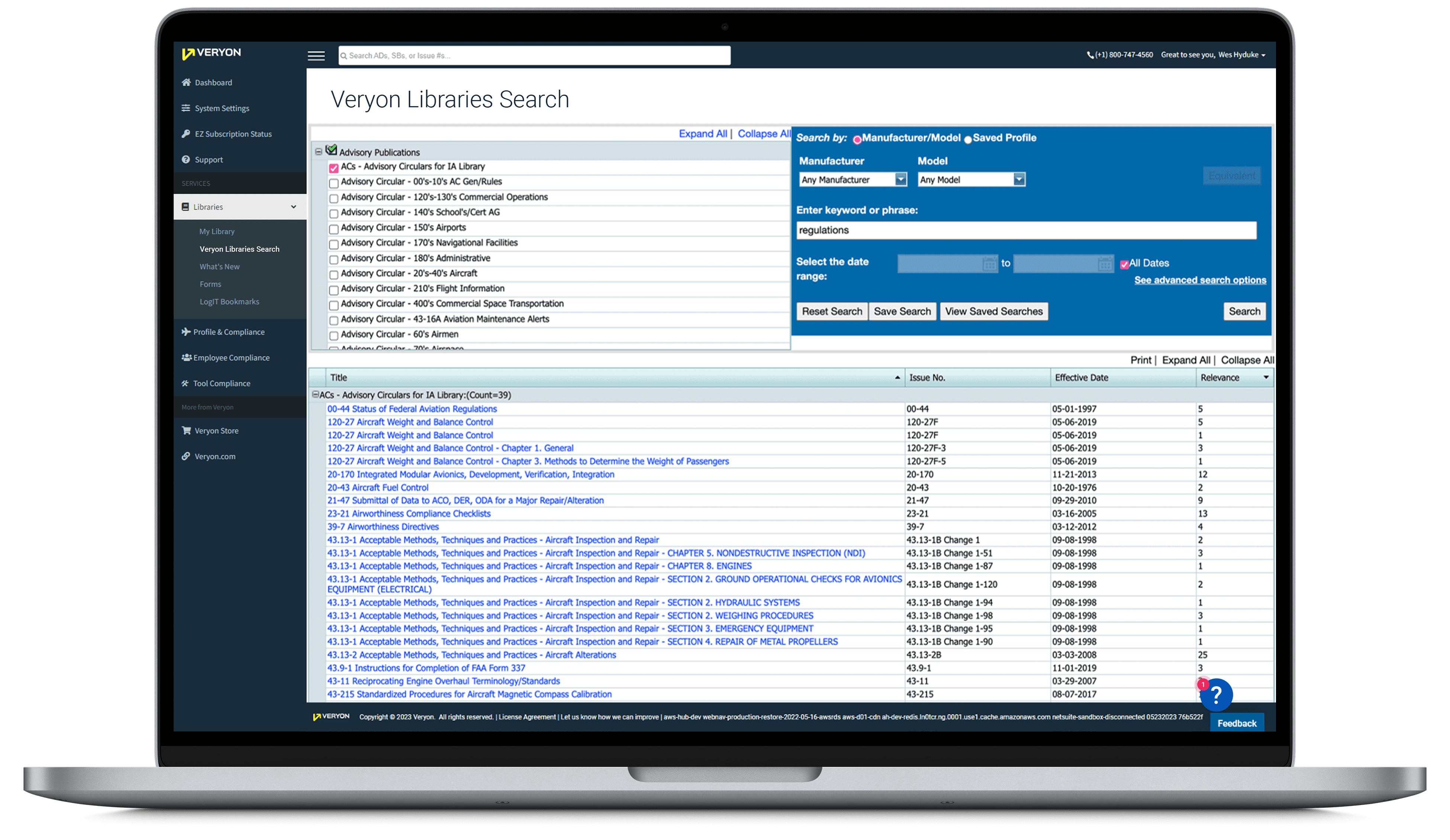

A single-source documentation product, one of our more popular solutions amongst aircraft operators and MROs, allows users to access aircraft technical manuals and publications for airframes, engines, propellers, wheels, brakes, batteries, starters, heaters, and other equipment — all from one central application.

Aviation maintenance management software and tech pubs, fully integrated.

Harness the power of Veryon Technical Publications directly within Veryon Tracking. Get access to your full library of aircraft tech pubs and regulator content with just one click from within the platform.

Recently, Veryon focused on an effort to migrate, modernize, and optimize the underlying infrastructure of its single-source documentation hub in order to make significant improvements to the user experience within the platform, and notably, there have been remarkable enhancements in terms of speed performance.

With this migration, users will find significant experience improvements within the all-cloud platform, including speed, efficiency, and increased functionality while searching for publications and looking up components.

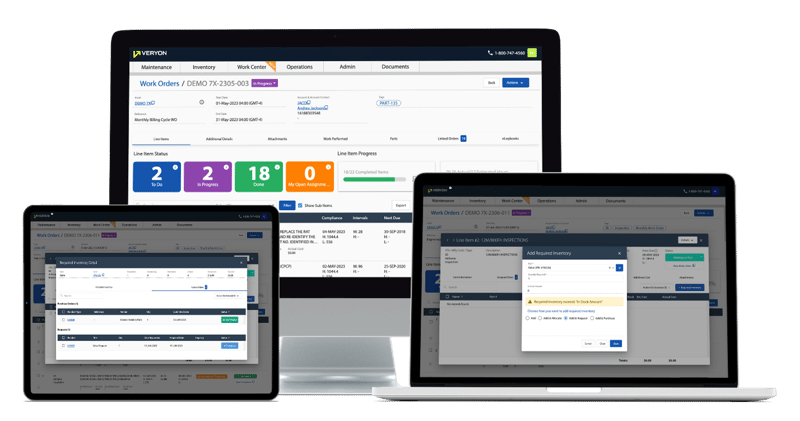

Veryon also recently unveiled Work Center, a comprehensive service center management solution that optimizes aircraft availability through efficient logbook generation, detailed tracking of costs and labor, customizable workflows, pricing profiles, and invoicing.

Work Center is part of the Veryon Tracking platform, which combines maintenance tracking, flight operations, inventory management, and technical publications in a single platform. Users can efficiently coordinate labor, parts, and operational impact seamlessly, ensuring smooth maintenance execution without any unnecessary delays or disruptions, as well as maximizing the availability of an aircraft, opening doors to short-notice charter opportunities, and expanding revenue potential.

Curious about how Veryon Work Center can help transform your aircraft operations? Watch as Kent Pickard, Vice President of Product Management, walks you through a comprehensive exploration of Work Center’s key features and its ability to streamline and simplify the process of returning aircraft to service.

What are some customers struggling with within their organization?

Mike Profit, Chief Operating Officer for Veryon, recently shared some challenges customers are facing and how utilizing more modern software can help alleviate those issues.

1. Shortage of skilled mechanics. Finding and retaining skilled mechanics can be a struggle. With the adoption of modern products and solutions, an organization can reduce the need for as many skilled resources.

- Utilizing a product like Veryon Technical Publications, users spend less time chasing the latest version of technical publications and more time keeping their aircraft flying with a single source documentation hub.

- Maintenance Tracking is another great tool to have in the toolbelt. With this solution, users can reduce the use of paper, improve efficiency, and track airworthiness, giving operators more aircraft uptime.

- Guided Troubleshooting can help determine where the problems are happening faster and improve first-time fix rates, resulting in a reduction of wasted resources.

" With Veryon Guided Troubleshooting, we can diagnose equipment problems 2-4X faster than with other methods, with almost no variation in elapsed time between rookies and experts."

Field Service Technician

Major OEM

2. Slow at adopting new technology

When it comes to influencing technicians and mechanics to change the way they’ve been working for years, it can be a challenge due to the increase in compliance risk moving from one system to another, the significant cost, and the utilization of valuable time.

- To combat this, choose software that is easier to use for the end users to help ease hesitation and eliminate barriers to resisting change.

- Focus on matching how technicians work today and simplifying their jobs, not forcing a new way of working.

- Eliminate some of the tools a technician has to use daily to do their job.

Conclusion

The adoption of more modern software solutions that offer mobile apps, real-time visibility, artificial intelligence, and integration, is imperative when it comes to growth, improved safety, and satisfying the ever-increasing demands of the industry worldwide.

Aviation management software is transforming the way our realm operates, which means the industry itself is positioned for an exciting future. To discover what Veryon can do for your team, contact us today for a free demo of any of our industry-leading solutions!